INTRODUCTION OF NEW GENERATION DIE CASTING MACHINE

![]() 2018-10-24

2018-10-24

With regard to die-casting machines technical specification, we can classify the die-casting machine into three different generations. The first generation of die-casting machines originated in the early 19th century. Its typical technical feature is manual injection, and is used for moveable type of printer production. The second generation of die-casting machines came out in the middle of 20th century. The typical technical feature is full automation hydraulic injection, and developed with single injection phase and multiplied injection phase. This generation of die-casting machines are used for low quality die-casting product production. The third generation of die-casting machines generated in the end 20th century. The typical technical feature is digital control system, and is used for high quality vehicle die-casting product production.

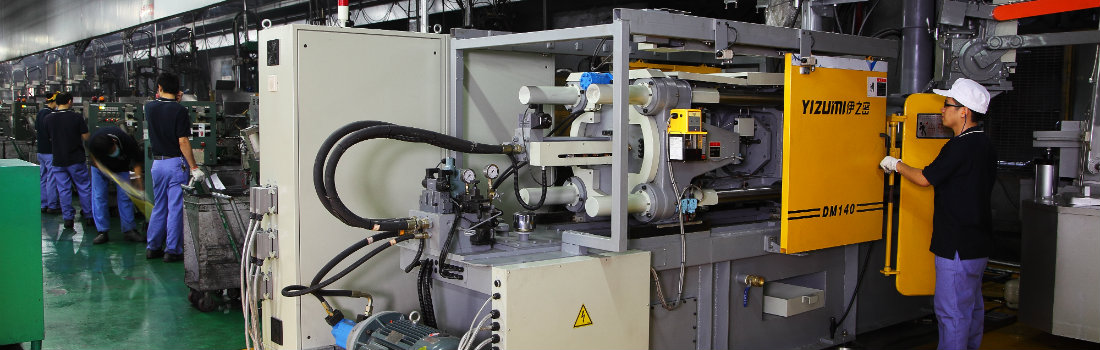

At the end of 2014, ZAMA SZ plant introduced two new die-casting machines with a digital control system. This new generation machine is not only equipped with digital technology, but also equipped with an intelligent quality online monitoring system. This means all the process parameters can be set digitally, and the system can display the real figures with curves. We can set the upper and lower limit value for the key process parameter, which influences the product quality significantly. If the real figures is out of limit specification, then an alarm will be set off to detect the defect.

With this new machine, the process data can be reserved once we obtain the good parts after adjusting the machine. The process data reserved can be used for the next lot production to produce good parts quickly. In the past five months of this new generation machine being in production, the reduction of average defect rate for some trouble-shooting product with a high defect rate is about 60 percent. At the same time, we saved a lot of change overtime. The intelligent digital control system is so simple that it can be used by a novice, whereas the traditional second generation of die-casting machines depended on the experience level of process technicians. Technicians always need to spend lots of time to try different process parameters to obtain the best parts and fix the process parameters by trying out the good parts.For almost each changeover, our process technicians need to adjust the process parameters. We always had the case where the second generation of die-casting machines produced the same product on the same die casting machine. In addition, we would produce the same product on a different die-casting machine but for a different batch. The defect rate is definitely different even if the process parameter is the same. Now the experience level of process technician is not so critical by using the third generation of digital control die-casting machine to produce good parts.

When the new generation of die-casting machine was introduced at ZAMA, the top management team and the experts from headquarters in Germany discussed how to improve the work conditions and work load; how to increase the machine‘s efficiency and lifespan; how to save energy and reduce waste; and how to reduce the risk of mechanical fires. For improving the work condition and work load, we moved to an oil pad to replace the traditional waste water ditch to collect the waste water. All the industrial pipelines are now installed above the ground instead of hiding under the ground to detect the leakage earlier and maintain the machine easier. The floor has been painted with bright color to enhance operator’s 5S concept. A single track crane replaced the double track crane to reduce the workload of die-mold changeover. In order to increase the machine‘s efficiency and lifespan, we invited machine manufacturers to train our operators on how to operate and maintain correctly. Now the daily, weekly, and monthly maintenance will be well done by the maintenance team. The two new machines were designed and installed with mirror concept instead of the normal installation concept to acquire maximum maintenance access. Because of this, there is no maintenance blind side. In order to save energy and reduce water waste, the new installation concept of one holding oven for two machines replace the traditional installation concept of one holding oven for one machine. By using heat resistant cooling pipes to improve the leakage problem, the statistical data indicated that 15 percent electricity energy was saved for the new machine and oven system and 70 percent water waste was saved for the new cooling system. For fire risks, the power hydraulic system and die release lube system of the new machine was designed by using non-flame hydraulic oil and non-flame die release lube. The melt material feeding location of the new holding oven is designed with new concept of keeping in the faraway location between the operators.

Copyright © 2018 Zama. All rights reserved.